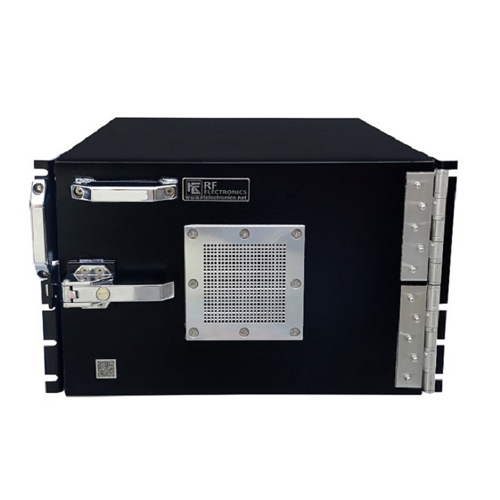

Durable and reliable electronic enclosures designed to safeguard your devices and ensure optimal performance.

About Us

RF Electronics was founded in 2002 and produces, develops, and maintains RF/microwave test equipment.

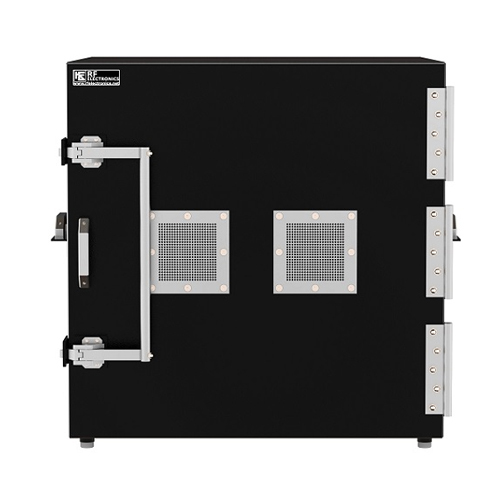

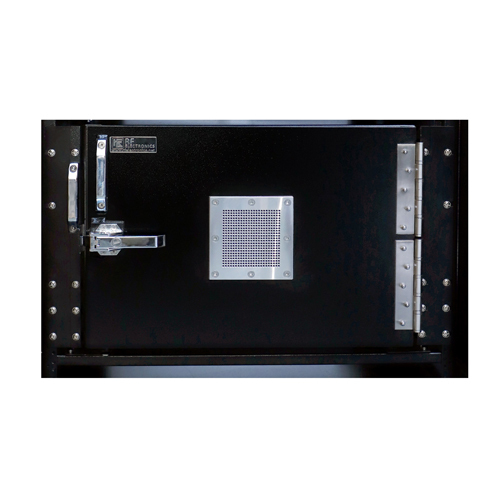

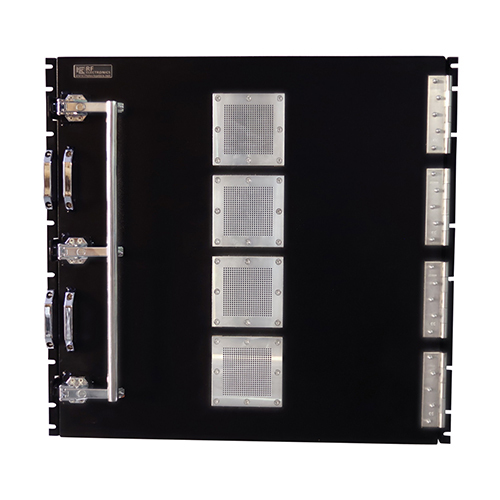

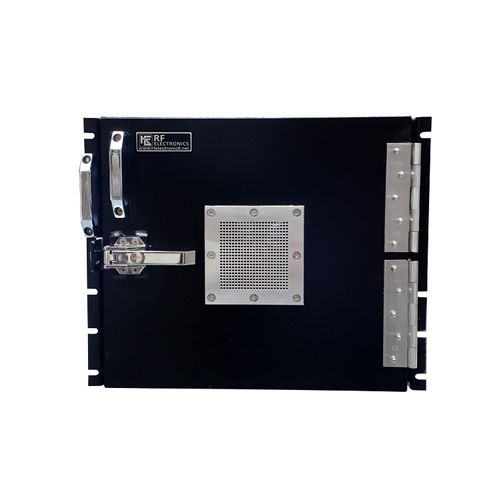

Hardik Electronics has created a product family of customized RF shield boxes, modularized filters, and pre-certified test beds with engineering skills based in RF equipment production and testing. These products set new standards for quality, cost, availability, and ease of use. Cutting-edge wireless technology testing, systems integration, and equipment assembly are all included in our Pre-Certified test bed services.

Specializing in design and development of Modular I/O Filter Plates

Modular I/O filter plates with a range of connector options are the specialty of Hardik Electronics. This makes the RF Shield Box, which is manufactured with modular I/O filter plates, easy to install and offers the best shielding effectiveness.

Customized integrated RF Shield Box for manual or automatic testing

For manual or automated testing, Hardik Electronics offers a bespoke integrated RF shield box at a price comparable to an off-the-shelf product. In addition to creating a fully functional, ready-to-use integrated RF shield box with a pre-certified test solution, Hardik Electronics fills the gap by offering the RF shielding required for repeatability while staying within your budget and time frame.

A variety of off-the-shelf computer accessories and networking components, such as motherboards, server chassis, hard disk drives, RAM modules, KVM switches, and media converters, are also offered by Hardik Electronics.

Why RF Electronics?

Industries We Serve

Quality Assurance

A result of strict control procedures incorporated into the manufacturing process.

At crucial points in the laser cutting and manufacturing process, every component is subjected to our exacting quality control.

Continuous performance evaluations conducted at the manufacturing location EMC Compliance, Insertion/Return Loss, Shielding Effectiveness, and Isolation Analysis are all guaranteed from the very beginning of product design testing in design verification.

Our Global Clients

Our clientele includes a variety of industry giants.

offering complete turnkey testbeds, anechoic chambers, and RF shielded boxes as tailored solutions to clients worldwide. covering every Wi-Fi spectrum, including 5G, mmWave, LTE, GSM, CDMA, and BT.

Our Facilities

Our facility is set up to guarantee top-notch research, sophisticated production methods, safe storage, and cutting-edge packaging.

The backbone of innovative engineering at RF Eelectronics is its full-fledged Engineering Centre.

For short project schedules, an experienced and highly skilled in-house CAD design team can quickly produce complex custom CAD design solutions.

The end-to-end fabrication, assembly, and testing pipeline at RF Electronics is well developed, guaranteeing the use of precise tools and the qualification of parts used in the product design using state-of-the-art equipment in-house. with numerous quality checkpoints at each level and a trained team.

To make sure that the filtered I/O modules and accessories used inside the shield box meet international standards for quality, RF Electronics has set up an emissions test equipment.

ENA (DC ~ 40GHz) is an in-house capital asset of RF Electronics.

In order to characterize the isolation of Shield Boxes with a faster turnaround time and greater testing precision, RF Electronics has also developed its own cutting-edge Robotic Radiated Emissions Test Setup (RRETS). This achieves accurate test measurement results with repeatability while removing human error and process variances.

To maintain the standard end-to-end manufacturing process, RF Electronics has a lot more advanced manufacturing and compliance equipment.

RF Electronics was founded in 2002 and produces, develops, and maintains RF/microwave test equipment.

Hardik Electronics has created a product family of customized RF shield boxes, modularized filters, and pre-certified test beds with engineering skills based in RF equipment production and testing. These products set new standards for quality, cost, availability, and ease of use. Cutting-edge wireless technology testing, systems integration, and equipment assembly are all included in our Pre-Certified test bed services.

Specializing in design and development of Modular I/O Filter Plates

Modular I/O filter plates with a range of connector options are the specialty of Hardik Electronics. This makes the RF Shield Box, which is manufactured with modular I/O filter plates, easy to install and offers the best shielding effectiveness.

Customized integrated RF Shield Box for manual or automatic testing

For manual or automated testing, Hardik Electronics offers a bespoke integrated RF shield box at a price comparable to an off-the-shelf product. In addition to creating a fully functional, ready-to-use integrated RF shield box with a pre-certified test solution, Hardik Electronics fills the gap by offering the RF shielding required for repeatability while staying within your budget and time frame.

A variety of off-the-shelf computer accessories and networking components, such as motherboards, server chassis, hard disk drives, RAM modules, KVM switches, and media converters, are also offered by Hardik Electronics.

Why RF Electronics?

- Recognized within the RF shield boxes enclosure and testing

- icon box 2

- Simple, Fast, Precision and Cost-effective Solutions

- 20+ years of experience

- 40+ exporting countries

- 299+ state of the art products

- 10000+ boxes supplied

- Fast delivery and future proof product

Industries We Serve

- Defence

- IoT Device Testing

- Telecommunication

- Industrial Automation

- Automotive

- Consumer Electronics

- Research Institution

- Radar Systems

- Medical Devices

Quality Assurance

A result of strict control procedures incorporated into the manufacturing process.

At crucial points in the laser cutting and manufacturing process, every component is subjected to our exacting quality control.

Continuous performance evaluations conducted at the manufacturing location EMC Compliance, Insertion/Return Loss, Shielding Effectiveness, and Isolation Analysis are all guaranteed from the very beginning of product design testing in design verification.

Our Global Clients

Our clientele includes a variety of industry giants.

offering complete turnkey testbeds, anechoic chambers, and RF shielded boxes as tailored solutions to clients worldwide. covering every Wi-Fi spectrum, including 5G, mmWave, LTE, GSM, CDMA, and BT.

- Lantronix

- Johns Hopkins University

- Broadcom

- Wipro

- Sophos

- Apple

- Qualcomm

- Intel

- Ruckus Wireless

- Mediatek

Our Facilities

Our facility is set up to guarantee top-notch research, sophisticated production methods, safe storage, and cutting-edge packaging.

The backbone of innovative engineering at RF Eelectronics is its full-fledged Engineering Centre.

For short project schedules, an experienced and highly skilled in-house CAD design team can quickly produce complex custom CAD design solutions.

The end-to-end fabrication, assembly, and testing pipeline at RF Electronics is well developed, guaranteeing the use of precise tools and the qualification of parts used in the product design using state-of-the-art equipment in-house. with numerous quality checkpoints at each level and a trained team.

To make sure that the filtered I/O modules and accessories used inside the shield box meet international standards for quality, RF Electronics has set up an emissions test equipment.

ENA (DC ~ 40GHz) is an in-house capital asset of RF Electronics.

In order to characterize the isolation of Shield Boxes with a faster turnaround time and greater testing precision, RF Electronics has also developed its own cutting-edge Robotic Radiated Emissions Test Setup (RRETS). This achieves accurate test measurement results with repeatability while removing human error and process variances.

To maintain the standard end-to-end manufacturing process, RF Electronics has a lot more advanced manufacturing and compliance equipment.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese